Al- Naboodah

The Challenge:

Among their numerous projects, AL Naboodah’s automobile workshop application, which focuses on repairing light and heavy vehicles, has experienced rapid growth, attracting a large number of vehicle owners. Despite having expert technicians and auto mechanics, managing the hefty workload became challenging. The need for a technical solution to reduce workload, enhance work efficiency, manage daily technician tasks, and monitor repair and maintenance status was evident.

The Solution:

To address these challenges, AL Naboodah decided to outsource an efficient team capable of converting their manual operations into automated processes. MMCGBL was selected to take on this task.

Project Kickoff:

Key Requirements

1.

In-House Intranet App: To enable technicians and in-house workers to manage daily tasks easily.

2.

Automation: To eliminate manual operations, save time, and decrease workload.

3.

Web and Mobile Apps: Developed in parallel, the web app would function as an intranet application, while a dedicated mobile app would cater to tablet users.

Features of the Workshop Automation Application:

1.

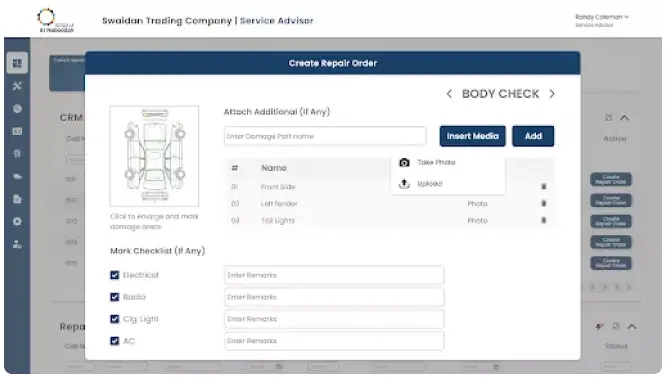

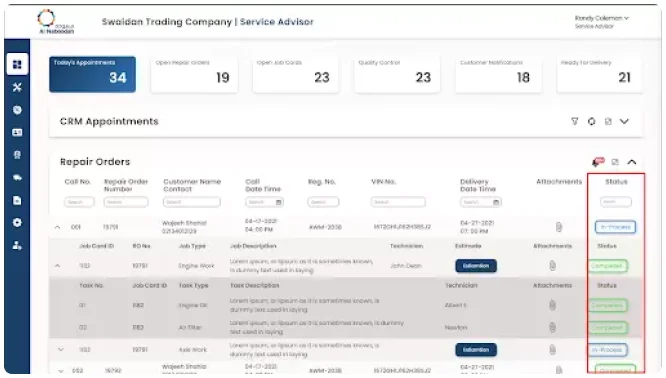

Repair Order Creation:

Records vehicle details, needed services, and customer information.

2.

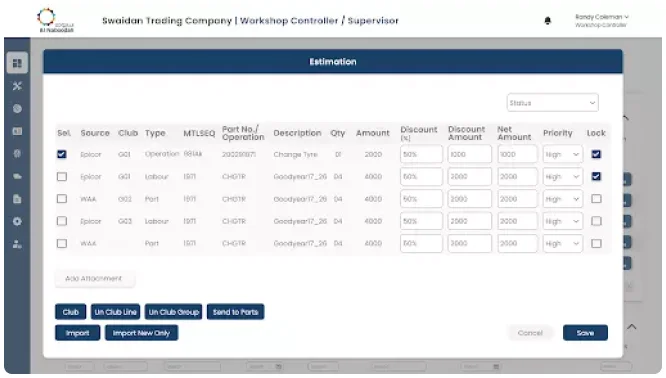

Estimation of Repair Orders:

Generates service cost estimations, including bundled service offers, and sends them to customers for approval.

3.

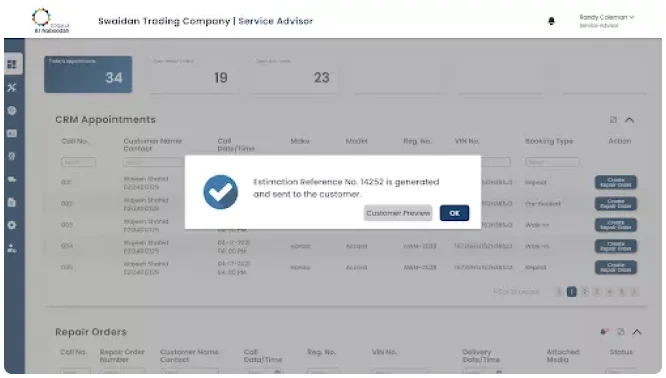

Estimation Sharing with Customers:

Integrates email notifications to inform customers about the estimated costs for approval or disapproval.

4.

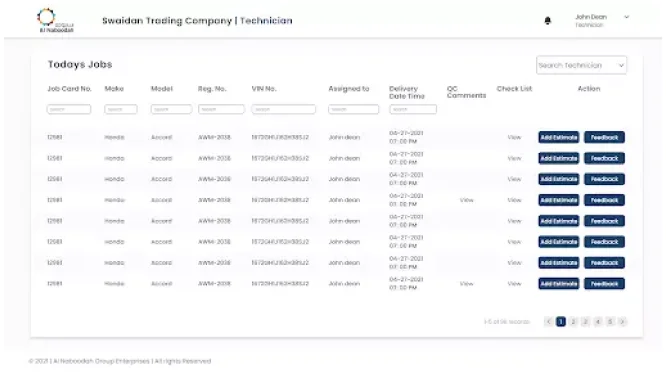

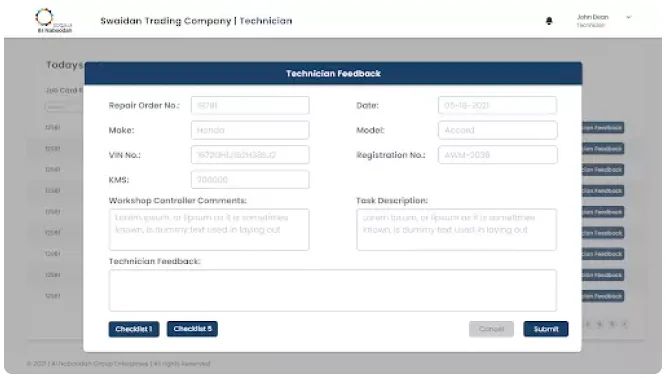

Technician Task Alignment:

Uses Epicor ERP to generate job cards, notifying technicians of assigned repair tasks.

5.

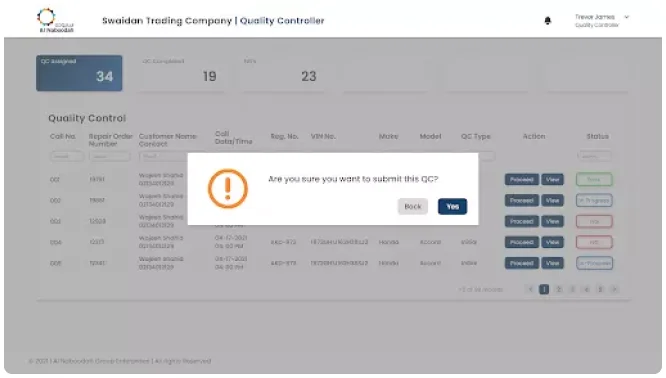

Quality Assurance of Vehicles:

Updates the repair status and assigns a final QA inspection. Any issues found are sent back for further adjustments.

6.

Vehicle Delivery Status:

Updates customers on the repair status and delivery via the app, keeping them informed throughout the process.

7.

Gathering Customer Feedback:

Allows customers to provide real-time feedback through the app, helping to improve service quality and address additional requirements.

Project Outcome:

Results:

The implemented automation significantly reduced workload, enhanced worker productivity, improved service performance, and ensured consistent service quality. It also enabled legitimate machine vision inspection and streamlined the overall workshop operations.

By adopting MMCGBL’s automation solution, AL Naboodah Group has achieved a transformative upgrade in their automobile workshop’s efficiency and customer satisfaction, paving the way for future growth and success.

Conclusion:

AL Naboodah Group’s partnership with MMCGBL has exemplified how technological innovation can revolutionize traditional operations, driving efficiency and improving service quality in the automotive repair sector.