The Predictive Data Analytics Boom In the Manufacturing Industry

The evolution of the manufacturing industry is booming with the potential of AI, enabling manufacturers to produce more in less time. But if you are the one who still chooses to use the old-school approach, you will only step back toward your downfall. Today’s challenges are modern solutions, and AI predictive data analytics can only solve problems once they arise like a pro.

AI helps us live in the future by using its complex algorithm, trained to understand behaviours, patterns, and other insights to predict future risks or opportunities and majorly influence decision-making. The manufacturing industry has been surviving on old-school tactics like manual data management, machinery faults records, maintenance hassles, on-hand workforce management, and almost all manual tasks that take time and cost to run manufacturing operations.

What Is Predictive Data Analytics In the Manufacturing Industry?

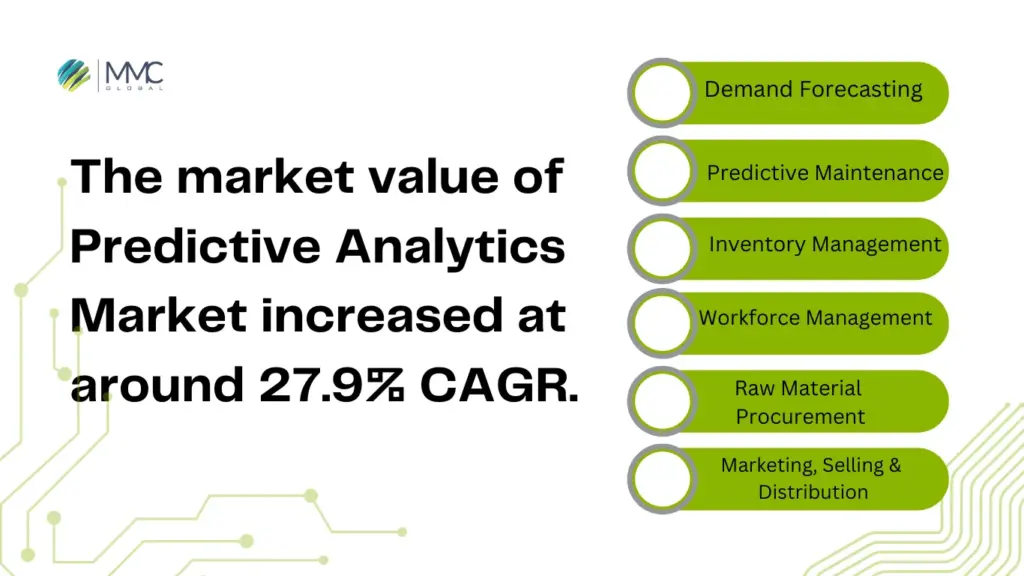

Predictive analytics is a high-end AI technology that uses machine learning, data analytics, and statistical models to analyze and evaluate historical data. In the manufacturing industry, predictive analytics forecast potential risks and opportunities and provide a crystal ball for making informed decisions. The global manufacturing predictive data analytics market share reached US$ 1,370.3 Million in 2023.

The crucial impact of data-driven strategies and workflows leads industries to a high level of success with more significant revenue streams. Data is the foundational source of handling diverse workflows. It can easily anticipate the required quantity of raw materials for manufacturing products, predict the demand and supply of the products, and analyze the ups and downs of marketing trends to streamline investment and production.

Although manufacturers previously controlled and monetized all the manufacturing, marketing, and distributing processes, there needed to be more certainty in the decisions because manufacturers relied on unsophisticated data rather than potential analytical-based insights. They were always at risk due to the need for more information and evaluation about what the market wants and what needs when.

Predictive analytics is a unique technology-based approach that eliminates the production failure risk, enabling manufacturing industries to thrive in this competitive edge. It is reported that 45% of manufacturers opt for predictive analytics to forecast market demands, gaining exponential business growth and reducing manufacturing overhead.

Predictive analytics inspect and evaluate diverse markets and attributes, such as demographic needs, customer behaviours, consumption patterns, customer acquisition channels, raw material requirements, and much more, collectively impacting the manufacturing process.

Moreover, Predictive analytics also empower manufacturers to detect manufacturing challenges like emerging machine faults, maintenance, and aunty vulnerability. Earlier, when predictive analytics did not intervene in the manufacturing process and conventional analytical approaches were imposed on companies, they encountered unannounced maintenance and faults after they blew up.

7 Applications of Predictive Data Analytics In the Manufacturing Industry

The manufacturing industry is getting more innovative with smart AI technology, thanks to predictive analytics that revolutionize informed decisions. Manufacturing is all about cranking out production smartly and distributing your product in high-demand areas by studying demographics.

We scrape out the diverse scope of predictive data analytics in the manufacturing industry. Let’s uncover the potential of data and analytics with AI in the manufacturing industry.

Demand Forecasting

What is better than knowing your customers’ demands before they even know? Interesting, right? Predictive data analytics perform flawlessly in studying and analyzing consumer behaviour, starting from their history of the buying journey.

Predictive data analytics accumulates information using complex algorithms and analyzes it using machine learning technology built into predictive analytics. By using advanced analytical techniques, modelling large datasets, and building solid frameworks, demand forecasting is now an emerging need of every manufacturing company.

Predictive Maintenance In Manufacturing

Machine faults were very unpredictable before the invention of predictive analytics. You might not expect them, and the machine might bite the dust for uncertain reasons. But no worries now if you integrate predictive data analytics in your manufacturing process. Predictive analytics can forecast machine malfunction, equipment failure, system errors, and other glitches before they get cracked.

Additionally, it reduces costs, reduces downtime, and maintains manufacturing continuity with no hassles. By tapping into the world of data and advanced levels of algorithms, you can protect your assets from malfunctioning before they snowball into a big mass. Manufacturing machines mainly contain IoT sensors that flow data in real-time and inform you of the 360-degree view of your machine’s efficiency. Auto maintenance scheduling is also a profound feature of predictive data analytics, enabling machine operators to analyze the machines and their equipment life span and revamp strategy.

Inventory Management With Predictive Analytics

AI-powered predictive data analytics help you monitor and track inventories, ensuring you analyze demand and supply processes. Monitoring and managing inventory carefully is essential as it affects manufacturing overhead, consumes time, and ultimately profits. For example, without analyzing the in-stock and over-stocked inventories, what is the point of pumping out products that are not in demand? Similarly, identifying out-of-stock inventories may lead to bad customer experience and can decrease your revenue.

Integrating predictive data analytics solutions in your inventory management process can help you overcome the above challenges by informing you what is good, what is better, and what will be the best. If you go manually, identifying what is in your warehouse is a highly complex process. Today’s business does not have time to wait for data collection from different departments before proceeding further. Implementing an inventory management system with predictive analytics technology will accumulate unified data from diverse connected business infrastructures, enabling you to click and have all data on your front. The predictive data analytic technique will help you quickly recommend your inventory management strategy.

Workforce Management In the Manufacturing Industry

Predictive analytics is your smart buddy for allocating your workforce efficiently. Identifying workforce requirements, shuffling shift timing, and measuring productivity set new standards in manufacturing factories. Everyone can understand the hectic workflow in the manufacturing department, like the pressure of achieving targets, flawless production, managing absenteeism, and appreciating workers to retain their workforce; all factors matter!

With the help of Predictive analytics and its TTPs, you can easily measure seasonal demand for staffing and overstaffing. Moreover, the amazing algorithm can also support you in monitoring staff performance by identifying their routing production patterns, predicting revenue, and analyzing skills gaps among the workforce.

Product Development Strategy & Manufacturing Execution

From product development to manufacturing execution, expert insights matter based on data. Developing a product requires in-depth research on market and consumer demand, competitor analysis, and a strategic plan that can turn product development into execution. Before indulging in manufacturing execution, creating a data-driven product development strategy is a proactive approach to eliminating the risk of failure.

Predictive analytics mitigate the risk of loss and time consumption, enabling the manufacturing industry to make informed decisions. Once the product development strategy is mapped out, predictive analytics provide a roadmap to execute the product manufacturing process. From allocating raw materials to your workforce to giving a ballpark figure of your investment to calculating the ROI, predictive analytics will support you like a pro!

Raw Material Procurement

Every successful product development results from effective raw material procurement management and strategy. It is a boss move to get help from raw material procurement and identify what, when, and how much you need to manufacture a complete product.

Predictive analytics also determined the cost of the product, the investment amount, and the risk of failure. It will ultimately understand the thin line between how economical your product will be, your target audience, and the other demographics. The cheaper or more expensive your raw material will be, the more you estimate the value of your final product. Further, you can also create a monetization strategy based on the investment amount.

Marketing, Selling & Distribution

Predictive data analytics is the backbone of the marketing, selling, and product distributing department, enabling the identification and setting of trends. Determining user behaviour, patterns, and value is essential to manufacturing products. Similarly, when you analyze the demand and finalize the product, it’s time to market your product to your target audience to ensure excessive sales. Once you finish your marketing and pre-selling activities, distribution to the spots where your audience can reach out quickly should be streamlined from your end.

That’s how all those Components associate with each other and function through predictive analytics. Predictive analytics help you identify your audience, track your sales pipelines, mark the conversions, and ensure your product reaches the right hand where you get the actual money of your investment.

How can MMC Global help manufacturing companies Implement predictive data analytics solutions?

MMC Global encourages industries to transform digitally with cutting-edge technologies like AI, enabling you to automate your business process to cut costs and time. We have been serving almost every sector, including manufacturing, to provide diverse solutions like ERP, CRM, AI-powered software, chatbots, etc., so take it easy and share your requirements with our experts to identify gaps, audit your IT infrastructure and suggest solutions to overcome your manufacturing challenges.

Let’s Wrap Up

Digital transformation is necessary in today’s business environment, and if you are still using old-school approaches, you are at high risk of trouble. AI and predictive data analytics are evolving technologies that help companies make more informed decisions, allocate resources effectively, and accelerate production to secure a high rate of custom acquisition.