Data is a critical weapon for small to large-scale businesses, and when it comes to the manufacturing industry, streamlined data can help in many ways. However, data management is pivotal for manufacturing companies as it can help proceed with manufacturing efficiently. A data-driven organization can actually grow faster and have multiple lucrative opportunities to expand its business.

Automation plays a vital role in streamlining data for manufacturing businesses. With the help of exclusive software and applications, companies are able to utilize, manage, and proceed with data. In this article, you will determine the importance of data management in manufacturing industries and what are the key features that make data management more fascinating.

Data Management in Manufacturing Industry

The conventional approach to data management is inefficient in handling complex or large amounts of data. In this cutting-edge era, data management is handled with futuristic software that unifies data from different resources. The data in the manufacturing industry can be operational workflows, supply chain data, logistics data, inventory data, warehouse data, energy consumption data, product manufacturing data, batch data, etc. A manual process does not work effectively to handle them on a large scale.

Let’s see how data management software can handle manufacturing data to make operations efficient.

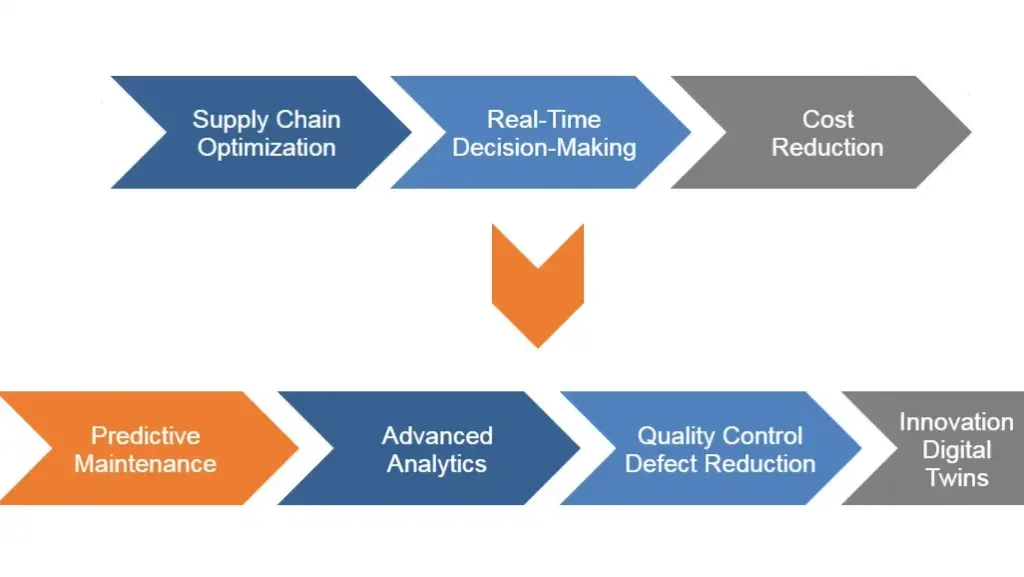

Benefits of Data Management In the Manufacturing Industry

Predictive Maintenance

Manufacturing data empowers predictive maintenance strategies by leveraging real-time information from sensors and IoT devices. By monitoring equipment health, manufacturers can anticipate potential failures and schedule maintenance activities proactively. This approach minimizes unplanned downtime, extends the lifespan of machinery, and optimizes maintenance costs. Predictive maintenance enhances overall equipment effectiveness, ensuring smooth and continuous production processes.

Process Optimization through Advanced Analytics

The utilization of manufacturing data allows for in-depth analysis of production processes. Through advanced analytics, manufacturers can identify inefficiencies, bottlenecks, and areas for improvement. This data-driven insight enables optimization of workflows, leading to increased operational efficiency. By continuously refining processes based on analytical findings, manufacturers can enhance product quality, reduce waste, and streamline their operations.

Supply Chain Optimization

Manufacturing data plays a crucial role in optimizing the supply chain. By analyzing data related to demand forecasting, inventory levels, and order fulfillment, manufacturers can make informed decisions to align production with market demand. This leads to improved inventory management, reduced carrying costs, and efficient order fulfillment, ensuring that products reach customers in a timely manner while minimizing excess inventory.

Real-Time Decision-Making

The availability of real-time manufacturing data facilitates quick and informed decision-making. Decision-makers can access up-to-the-minute information on production status, quality metrics, and resource utilization. This enables agile responses to changing conditions on the shop floor, allowing for adaptive production planning and resource allocation. Real-time decision-making is critical in a dynamic manufacturing environment, contributing to improved responsiveness and agility.

Quality Control and Defect Reduction

Manufacturing data is instrumental in enhancing quality control processes. By analyzing data from various stages of production, manufacturers can detect patterns and anomalies that may indicate potential quality issues. This proactive approach helps in identifying and rectifying defects early in the manufacturing process, reducing the likelihood of producing faulty products. Improved quality control contributes to higher customer satisfaction and loyalty.

Cost Reduction and Operational Efficiency

Efficient data management in manufacturing leads to cost reduction and improved operational efficiency. Through data-driven insights, manufacturers can identify areas where resources are underutilized, implement energy-saving measures, and optimize production schedules. This not only reduces operational costs but also enhances overall efficiency, allowing manufacturers to produce more with fewer resources.

Innovation through Digital Twins

Manufacturing data facilitates the creation and utilization of digital twins, virtual replicas of physical systems or processes. Digital twins enable simulation and modeling, providing a platform for innovation and experimentation without impacting actual production. Manufacturers can test and optimize new ideas in a virtual environment, fostering continuous improvement and technological innovation.

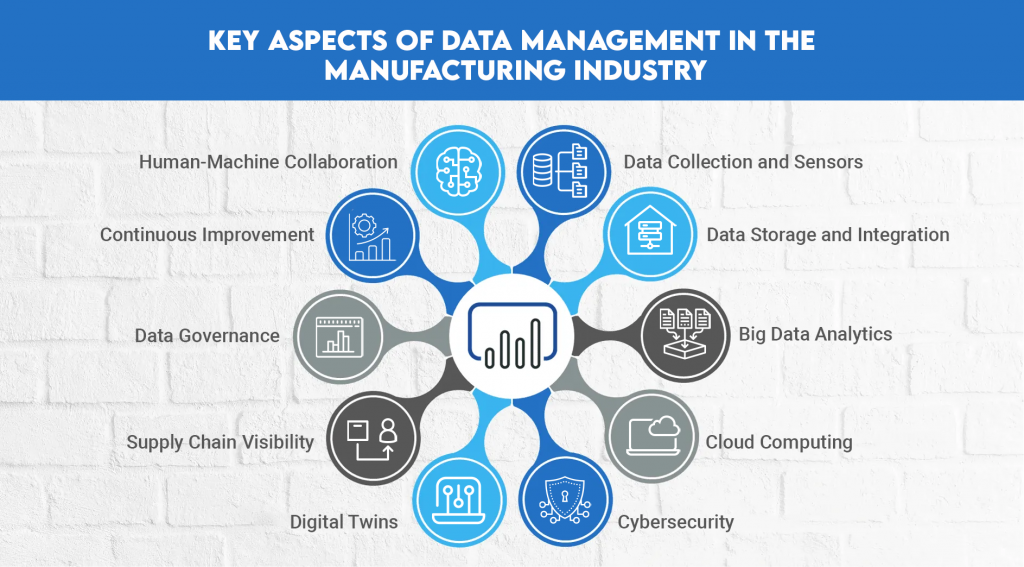

[Nasir-hu-mein heading=”Data Management Software & Solution” para=”Transform your data into actionable insights – because in the world of manufacturing, every byte matters!”]Key Aspects of Data Management In the Manufacturing Industry

Data management in the manufacturing industry is a critical aspect that involves data collection, storage, processing, and analysis to improve efficiency, quality, and overall operational performance. As manufacturing processes become more complex and technology-driven, effective data management becomes increasingly essential. Here’s a detailed review of key aspects of data management in the manufacturing industry:

Data Collection and Sensors

Sensors and IoT Devices: In modern manufacturing, sensors and Internet of Things (IoT) devices play a pivotal role in collecting real-time data from various stages of the production process.

Machine Monitoring: Monitoring equipment health and performance through sensors enables predictive maintenance and reduces downtime.

Data Storage and Integration

Data Warehousing: Manufacturers often use data warehouses to store large volumes of structured and unstructured data. This facilitates easy retrieval and analysis.

Integration of Systems: Integration of various systems like Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and Product Lifecycle Management (PLM) is crucial for a seamless flow of information.

Big Data Analytics

Predictive Analytics: By analyzing historical and real-time data, manufacturers can predict maintenance needs, optimize production schedules, and identify potential quality issues before they occur.

Quality Control: Big data analytics can enhance quality control processes by identifying patterns and anomalies in production data, leading to improved product quality.

Cloud Computing

Scalability and Flexibility: Cloud-based solutions provide manufacturers with the scalability and flexibility needed to handle large datasets and accommodate changing business requirements.

Collaboration: Cloud platforms facilitate collaboration among different departments and even across multiple manufacturing facilities.

Cybersecurity

Data Protection: With the increasing connectivity, ensuring the security of manufacturing data is crucial. Robust cybersecurity measures protect sensitive information from unauthorized access and potential cyber threats.

Regulatory Compliance: Compliance with data protection regulations is paramount, especially in industries with strict standards and regulations.

Digital Twins

Simulation and Modeling: Digital twins create virtual replicas of physical systems, enabling manufacturers to simulate and optimize processes before implementation. This can lead to improved efficiency and reduced waste.

Real-Time Monitoring: Monitoring the digital twin in real time allows for better control and responsiveness to changes in the manufacturing environment.

Supply Chain Visibility

End-to-End Visibility: Data management includes supply chain processes beyond the factory floor. Real-time visibility into the entire supply chain helps forecast demand, inventory management, and order fulfillment.

Data Governance

Quality Management: Ensuring data accuracy and reliability is critical. Data governance frameworks help define policies, standards, and processes to maintain high-quality data.

Data Ownership: Clearly defining data ownership and access rights ensures that the right personnel have access to the right data.

Continuous Improvement

Performance Metrics: Establishing key performance indicators (KPIs) and regularly analyzing them allows manufacturers to identify areas for improvement and optimize processes continuously.

Feedback Loops: Data management facilitates the creation of feedback loops, enabling manufacturers to learn from past experiences and make informed decisions for ongoing improvement.

Human-Machine Collaboration

Decision Support Systems: Empowering decision-makers with data-driven insights enhances decision-making, leading to better strategic choices.

Employee Training: Data management supports training programs for employees to operate and maintain advanced manufacturing technologies.

In a Nutshell

the integration and effective management of manufacturing data are transformative for the industry, yielding numerous advantages across various facets of operations. The benefits are substantial, from predictive maintenance that minimizes downtime to advanced analytics-optimizing processes and real-time decision-making that enhances agility. Supply chain optimization, quality control improvements, and cost reduction further underscore the significance of leveraging data in manufacturing.

Additionally, the innovative potential unlocked through digital twins contributes to continuous improvement and technological advancements. As the manufacturing landscape evolves, harnessing the power of data ensures operational excellence and positions companies at the forefront of competitiveness, adaptability, and innovation in an increasingly data-driven era. Embracing robust data management practices is, therefore, a necessity and a strategic imperative for manufacturers looking to thrive in the dynamic and complex environment of modern industrial production.